With so much uncertainty and vulnerability in global trade and shipping, companies/businesses must adopt technology to improve transparency and synchronize all aspects of the supply chain, especially inventory management, costs, and intake margins.

Today retailers have far too much inventory already landed with more en route, merely to go into markdowns, creating high additional off-site storage costs and lower margins. Rent, detention, and demurrage costs are at an all-time high due to ‘not knowing exactly where your product is, ‘ and with various strikes and a lack of labor and or equipment make the overall problem significantly worse.

Today retailers have far too much inventory already landed with more en route, merely to go into markdowns, creating high additional off-site storage costs and lower margins. Rent, detention, and demurrage costs are at an all-time high due to ‘not knowing exactly where your product is, ‘ and with various strikes and a lack of labor and or equipment make the overall problem significantly worse.

Why is there too much inventory and additional costs? To truly understand the end-to-end position, there needed to be more low-level order management visibility within the supply chain and more data-led analytics throughout the critical path, especially within the first mile. Coupled with ongoing disruption levels needing to be genuinely understood using the same analytics to address the constant disruption, order levels, and demand. Then comes along a global downturn in consumer demand. Not knowing what is happening due to insufficient visibility and trust delivers a lack of clarity and results in poor planning and decision-making. These are big contributors to why there is too much inventory in the market.

Are there any signs of less disruption or even a recovery? Answer: No. Economists, Governments, Banks, and the major shipping lines are all predicting dark clouds ahead.

I mention the shipping lines as, traditionally, they have been a good barometer of what’s coming in the global economy and are typically very quick to react when the economic outlook looks grim. They are very good at removing capacity and easing pressure on their costs when demand softens. It still costs them to remove capacity but nothing like sailing half-empty across the various trade lanes. However, it comes at an altogether different cost. Disruption.

The carriers have had unprecedented profit levels for the last couple of years, but that is about to change. They have been trying to keep rates relatively high and stable throughout the past few months with blank/void sailings, yet this has yet to work, and it won’t. The idling up of existing vessels is now inevitable, if not already occurring, creating more disruption. An imbalance of containers in the correct origins will fuel additional costs and further disruption as we move through the coming months. The carriers will do whatever it takes to keep their costs low and remain somewhat profitable despite all the new capacity entering the markets from 2023. This will result in continuous disruption despite demand volumes being low.

The carriers have had unprecedented profit levels for the last couple of years, but that is about to change. They have been trying to keep rates relatively high and stable throughout the past few months with blank/void sailings, yet this has yet to work, and it won’t. The idling up of existing vessels is now inevitable, if not already occurring, creating more disruption. An imbalance of containers in the correct origins will fuel additional costs and further disruption as we move through the coming months. The carriers will do whatever it takes to keep their costs low and remain somewhat profitable despite all the new capacity entering the markets from 2023. This will result in continuous disruption despite demand volumes being low.

For importers and exporters, there will be fewer sailing options, resulting in longer lead times and continuous risk and disruption to planning and, ultimately, the top and bottom lines. There is already far too much uncertainty, and this is not about to change—bank on more delay and continued disruption. However, you can plan to mitigate risk using technology.

The use of technology within the supply chain is an essential component of any business, not just from a visibility aspect but also for continuity, transparency, and forecasting with accuracy to minimize costs, improve customer service and protect margins and cash flow.

The supply chain starts much earlier than a container ready to leave a port of origin and significantly earlier than a few days before it reaches the destination port. An agile supply chain is designed to deliver around a purchase/sales order, and the component levels within the order are the consumer demand and hugely relevant.

Having a single digitized source of truth from the buying floors, merchandisers, planners, manufacturers, import departments, logistics providers, carriers, and the DCs at the ORDER level down to SKU/item/part level is critical. This is the supply chain, and it must not be Siloed internally or externally. Supply chains must be proactive to change and manage at the lowest denominator from start to finish, including the physical shipping aspect.

Having a single digitized source of truth from the buying floors, merchandisers, planners, manufacturers, import departments, logistics providers, carriers, and the DCs at the ORDER level down to SKU/item/part level is critical. This is the supply chain, and it must not be Siloed internally or externally. Supply chains must be proactive to change and manage at the lowest denominator from start to finish, including the physical shipping aspect.

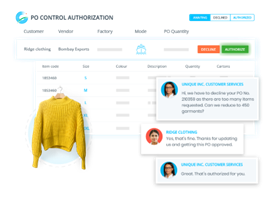

The @Gravity Supply Chain Solutions Order Management platform delivers cohesive, synchronized, data-driven actionable insights throughout the critical path. We enable transparency, accountability, and a value chain by connecting all direct and indirect stakeholders. You now have complete governance and control of your supply chain to meet business and consumer demand from the first mile.

I can only speak for Gravity, but the cost of adoption is significantly cheaper than not having accurate, timely visibility of the risk of disruption, failure, and margin erosion. Not having a fully connected end-to-end visibility platform directly or via your service providers is unacceptable in today’s world.

Come and speak with us and allow us to showcase how we enable you to take control of your supply chain/your customer’s supply chains, mitigate risk and gain a competitive advantage over your competitors.

CEO Gravity Supply Chain Solutions.