DEFINITION

Supply chain synchronization is an ecosystem of connected, collaborative data partners, whereby information gets collected, analyzed, and utilized in real time. All stakeholders within the critical path obtain accurate visibility, identify weaknesses, streamline processes, and mitigate risk.

HISTORICALLY

Early supply chains operated using the necessary process of moving materials manually along a largely linear chain from the point of origin to the end consumer, and this was initially considered an efficient, well-run supply chain. However, this is no longer so!

EVOLUTION

Supply chains have evolved significantly over recent years:

- network sizes have increased

- speed of change has accelerated

- levels of transparency have shifted

Getting products to market requires the modern, complex supply chain to utilize a far greater level of coordination.

INCREASED PERFORMANCE

Our original blog highlighted how Henry Ford introduced the first assembly line in 1913. In doing so, he reduced the time it took his workers to assemble a Model T car from 12.5 hours to under two using three qualities factory floor managers share with today’s supply chain and logistics professionals:

- speed

- efficiency

- reliability

ENHANCED VISIBILITY

![]()

As supply chains continue to expand globally, they can become increasingly fragmented and complex. Digitization to enhance visibility and enable the orchestration of all inventory movements by connecting all stakeholders within the critical path has become essential.

THE PRESENT

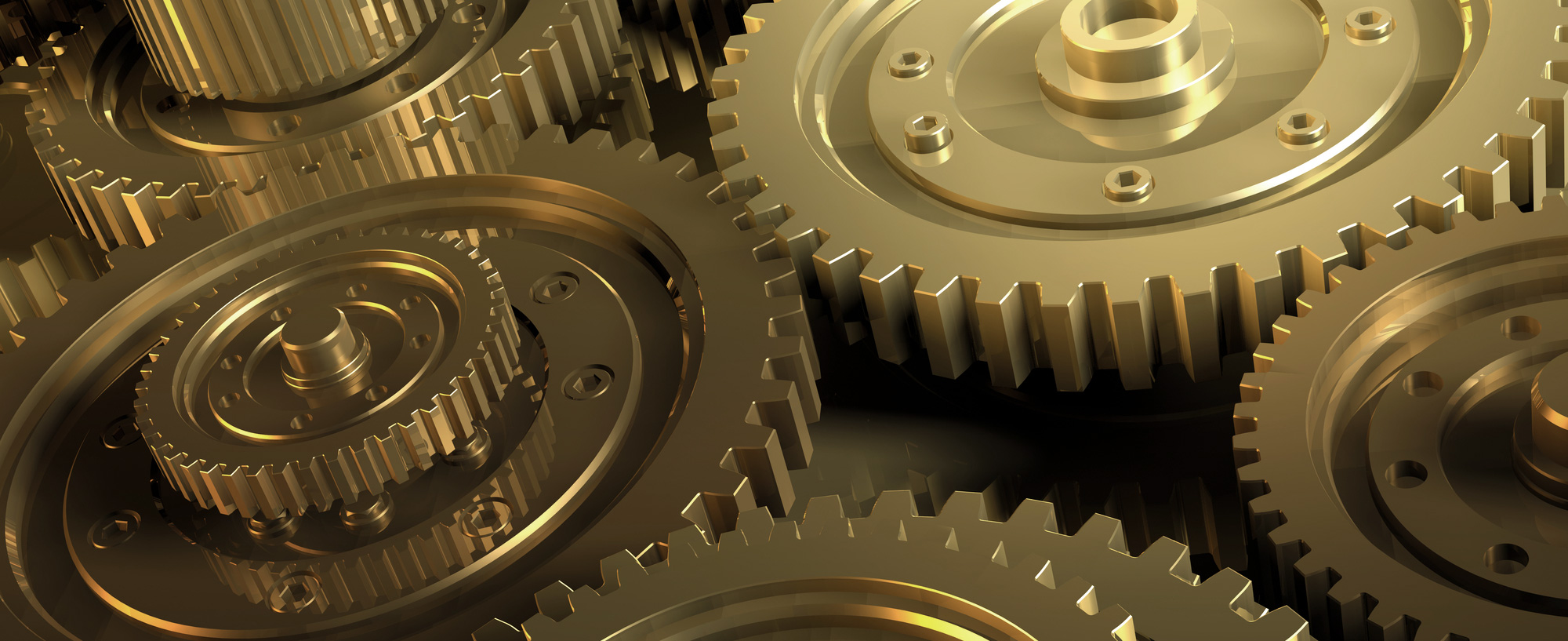

The modern-day supply chain is no longer linear, but instead, more closely resembles the innards of a fine Swiss watch, with numerous individual parts needing to work together 24/7.

Deploying digital technology empowers supply chains by creating powerful ecosystems that provide a business-wide view of entire operations. Optimizing supply chains using high levels of connectivity from purchase order to destination allows for the mitigation of risk, and the ability to make data-driven decisions with certainty.

SYNCHRONIZATION

Achieving this level of supply chain synchronization has never been more difficult, but it is possible!

Businesses need to rebalance their supply and demand to react with the speed and agility expected by the modern-day consumer. Optimizing the supply chain helps to:

- Build a responsive supply chain with increased performance

- Improve collaboration between manufacturer/supplier and shipper

- Increase lines of communication between all stakeholders

- Reduce costs, increase sales, and protect the bottom line

- Manage inventory levels to improve fulfillment rates and product availability

AVOID THE OBSTACLES

Companies must avoid the five most common ‘obstacles to synchronization’ across the supply network, as these often spell the difference between success and failure. Let’s examine these closely intertwined obstacles and evaluate how one problem leads to another, on to another, and how the chain-reaction then continues at an unabated pace.

OBSTACLE 1: LACK OF COLLABORATION

All too often, companies work in silos between various departments or geographical locations, etc. However, lack of collaboration can have a significantly negative effect on business due to the increased time it takes to make critical decisions and mitigate risk. The result of a survey conducted by PwC – ‘Supply chain and risk management – Making the right risk decisions to strengthen operations performance‘ indicates that companies consider the alignment between partners in the supply chain as the most crucial factor in enabling risk reduction (60%).

Complete end to end supply chain transparency is essential for a streamlined and fully optimized supply chain. There is no doubt that the sharing of data and objectives enables collaboration and trust between all stakeholders. However, businesses must learn to collaborate internally to allow them the opportunity to create successful collaborative relationships with external partners.

OBSTACLE 2: LACK OF TRUST

Lack of collaboration and communication breeds mistrust – not in one another, but in the data that comes streaming into legacy systems such as email inboxes, shared spreadsheets, etc.

Trust is, in fact, one of the most critical factors in an effective and efficient supply chain that’s committed to collaborative partnerships.

However, trust can only come about if all stakeholders within the supply chain share the critical information required to build reliable supply chain processes as a result of trusted data and partnerships.

OBSTACLE 3: LACK OF VISIBILITY

Visibility is essential for the supply chain to operate effectively in today’s fast-paced and consumer-driven global network where trust is business-critical. An inability to collaborate to identify and solve problems makes it impossible to achieve end-to-end supply chain visibility. According to a study by the Business Continuity Institute, 72 percent of suppliers who have dealt with a breakdown in their supply chains have lacked the full visibility needed to come up with a fast and simple solution. You mustn’t make the same mistake! Having a thorough and complete understanding of every element of your supply chain, and the contingency plans set in place from your suppliers will help you plan ahead and appropriately respond when a disruption occurs.

OBSTACLE 4 – LACK OF REAL TIME INFORMATION

The primary factor that creates a lack of visibility and lack of trust is an inability to monitor and share information in real time. Too often, when one partner reaches out to another for information, the response received is outdated and incomplete. This lack of detailed information in real time, means decisions get made, and actions get taken, on information that can be significantly ‘out of date.’

Having access to real time data is a necessity. Setting up automated ways of monitoring the Web for relevant “breaking news” allows you and your partners the ability to collect and share real time data. Leveraging technology by deploying near real time visibility solutions such as that offered by the Gravity platform, makes the process of reacting to the unexpected quicker and easier. It allows businesses to mitigate the potential risk of the numerous disruptions that can happen at any time and can have a significant impact on multiple aspects of your business.

OBSTACLE 5: INABILITY TO MITIGATE DISRUPTIONS

The above factors force the supply chain to be reactive, rather than proactively anticipating, disruptions. The truth is, many companies accept that disruption is inevitable, and extend lead times to compensate rather than using technology to identify, evaluate, and mitigate areas of risk and exposure. This process impacts working capital as well as increases pressures on stockholding facilities unnecessarily.

If these are the prevailing attitudes, imagine the competitive advantages you can create if you can overcome these five obstacles by digitizing your supply chain!

If you want to learn more about how Gravity’s platform can take the complexity out of your supply chain by leveraging digital synchronization to benefit your business, contact us here, and one of our advisors will be in touch.