In our previous blog post ‘The Evolution Of The Supply Chain’ we looked at what changes occurred within supply chains over the last two decades; in this article, we will highlight areas that need addressing to ensure the success of the future supply chain:

MANUAL PROCESSES

Regardless of how often businesses are made aware of the need to shift away from manual processes, some mindsets are reluctant to embrace necessary software innovation changes. This reluctance results in the risk of becoming less relevant or possibly even irrelevant in the fast-paced evolutionary world we live in by not evolving at an exponential rate required.

Take a moment to think… please open your email inbox right now. You will almost certainly have an email waiting for you that has a spreadsheet attached and that email has likely got numerous people copied into it too. Breaking the routine of using manual processes can be a hard habit to break. However, this behavior change needs implementing from the very top C-Level Executives right through to the younger members of staff who already live their lives digitized and will likely be able to accept the need for change and convert with ease! Spreadsheets and other similar office operations are easy to implement, learn, and use. They are highly portable, simple to share, and come with very little financial outlay; however, they are not the future and should not be considered acceptable.

POOR DATA QUALITY

Data quality is critical to ensure supply chains function at a truly optimized level. However, if you are still using manual processes to manage your business, the quality of data getting shared by external trading partners often becomes of poor quality as a result of crunching through the data presented from the numerous parties involved. It is no longer live real time information, which results in a significant onus on businesses to spend extra workforce hours and effort cleaning the data to get to the truth.

A study performed by the Supply Chain Resource Cooperative showed that the majority of senior management members have little awareness regarding the impact poor data quality has on decision-making and:

- 15% of respondents believe existing systems are capable of producing clean trustable data

- 20% more respondents emphasized that they spend more than one-quarter of their day searching for data.

COLLABORATION VS. COOPERATION

One of the outstanding features of collaboration is that when a project or task gets performed, it does so with the input of numerous stakeholders who work together to meet with a conclusion that cannot get attributed to any singular person or team. Collaboration is not something that can be performed by a group of strangers. Having a deep understanding of the motivations that influence the partners getting worked with and appreciating their views and opinions helps drive processes removing the risk of fragmented operations, which inevitably result in poor decision-making.

In simple terms, cooperation is when people work together; however, the confusion between being pleasant and understanding while working in this way often gets confused with the need to ‘collaborate’ with a flexible approach to align goals and resources in real time to achieve the best possible outcome.

SILOS

The words ‘remove supply chain silos’ are not new; they have been resounding throughout the industry for many years, with 2020 getting heralded as the ‘Golden Year’ for turning things around to benefit from more agile processes.

However, within the retail, manufacturing, and logistics industries, silos remain a persistent obstacle, preventing the unification of teams from leveraging the best outcomes, and individuals continue to operate independently with their objectives to the fore.

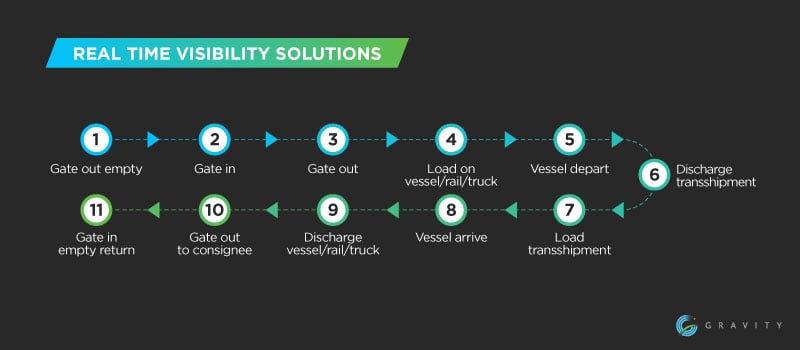

SUPPLY CHAIN VISIBILITY

Fortunately, significant inroads have occurred into increasing levels of supply chain visibility through the deployment of real time visibility solutions such as those offered by Gravity’s platform.

However, a true end to end supply chain visibility for some companies remains a challenge due to:

- Lack of investment in time, money and resources

- Visibility – the evolution of networks, technologies, regulations, business models, and competitors is fast-paced. It requires businesses to have timely, accurate, and complete visibility throughout the critical path to ensure responsible safety, environmental, and legal practices get executed.

CHANGE MANAGEMENT

The implementation of new technologies and processes requires enormous amounts of change management to take place. It is simply not enough to continue with the ‘this is the way we’ve always done it, and it works okay so we don’t need to change it’ type attitude. The need for mindsets to change is business-critical but remains one of not ‘the’ most significant hurdles. Popular brands that don’t embrace the need to digitize every aspect of the business, including the supply chain, will find themselves less prevalent in the eyes of today’s on-demand consumer.