In my previous blog post – “Frictionless: The New Supply Chain Competitive Advantage,” I wrote about the problem that Gravity Supply Chain Solutions has set out to solve – helping businesses deliver frictionless customer experience. In this post, I’ll provide examples of friction points in a real-world supply chain, and identify specific areas you can improve right now to start developing a competitive advantage.

It’s very likely that you’ve heard about the frictionless customer experience when reading about Uber or Amazon. Uber removed four points of friction from taking taxis:

- Waiting time.

- The need to call a driver.

- Giving clear directions to the destination.

- Payment.

We see these same types of friction points in the supply chain.

|

| Customer Experience Data Drives Key Decisions, AudienceView, audienceview.com |

For the vast majority of businesses, their supply chains are anything but frictionless. The fragmentation that exists between all the parties, from the manufacturer to the logistics provider, right through to the consumer is staggering.

Summary Of Supply Chain Process Map Findings

Recently, we helped a global logistics provider carry out some research in conjunction with a few of their customers and their customers’ trading partners. We mapped out all the process steps that occur between the placement of an international product purchase order with the manufacturer, right through to the receipt of that product in the warehouse at destination.

On average we found:

- There were over 200 process steps taking place in just one movement.

- More than 10 different trading parties, or separate businesses, were involved alone in the first tier.

- There were over 50 people spread across these companies who could get involved at some point.

- Excluding Excel, on average 12 different systems were touched somewhere

- Of those systems, only two or three shared data, the rest operating in its own silo.

However, the above doesn’t even represent a true end-to-end supply chain because it doesn’t include what takes place before the purchase order gets placed, or what happens to that product once it has reached the first warehouse stop at destination.

In short, you have 200 friction points in your supply chain where something could go wrong.

Imagine, 200 points, 50 people and 12 systems where data is getting passed around manually, often several days after generation. Add in the risk of external disruption factors such as the weather, and you can see the challenge companies face in trying to move from product-centric to customer-centric.

I’m sure this may sound familiar to what many of you have previously have wrestled, or are currently grappling with in your business.

That’s where Gravity Supply Chain Solutions comes into play. In the above scenario, we become the thirteenth and most important system. We are the platform that can bring all the other systems together so that they talk to each other, or replace those no longer needed, and indeed, if a system doesn’t already exist, we fill that gap.

Four Ways Gravity Supply Chain Removes Friction Points In Your Supply Chain

Once we do that, we remove friction in four key areas:

Firstly: Real Time Visibility.

For us real time doesn’t necessarily mean knowing what is happening today, it’s more about taking that and using it to understand what is going to happen in the future.

Most supply chains operate in data silos. Take a vessel, for example, it arrives at a port and somewhere, somebody with a product on it receives an email. That email is then passed on and on and eventually ends up in a spreadsheet, or keyed into a system. That can take days. And if that vessel arrives late, somebody somewhere tries to work out what that means.

We take the view of ‘why can’t we just go and get that information from the source and use that to predict what is going to happen next?’ The port knows the vessel is there. The vessel knows it’s there, so why don’t we bypass that manual information chain and tell people automatically what’s happened, and more importantly what’s going to happen next.

That’s what we believe real time visibility in the supply chain means; cutting out all those manual processes and friction points and getting the data directly to our users so they can make use of it, with the net result being that the supply chain becomes quicker and more agile.

Secondly: Collaboration.

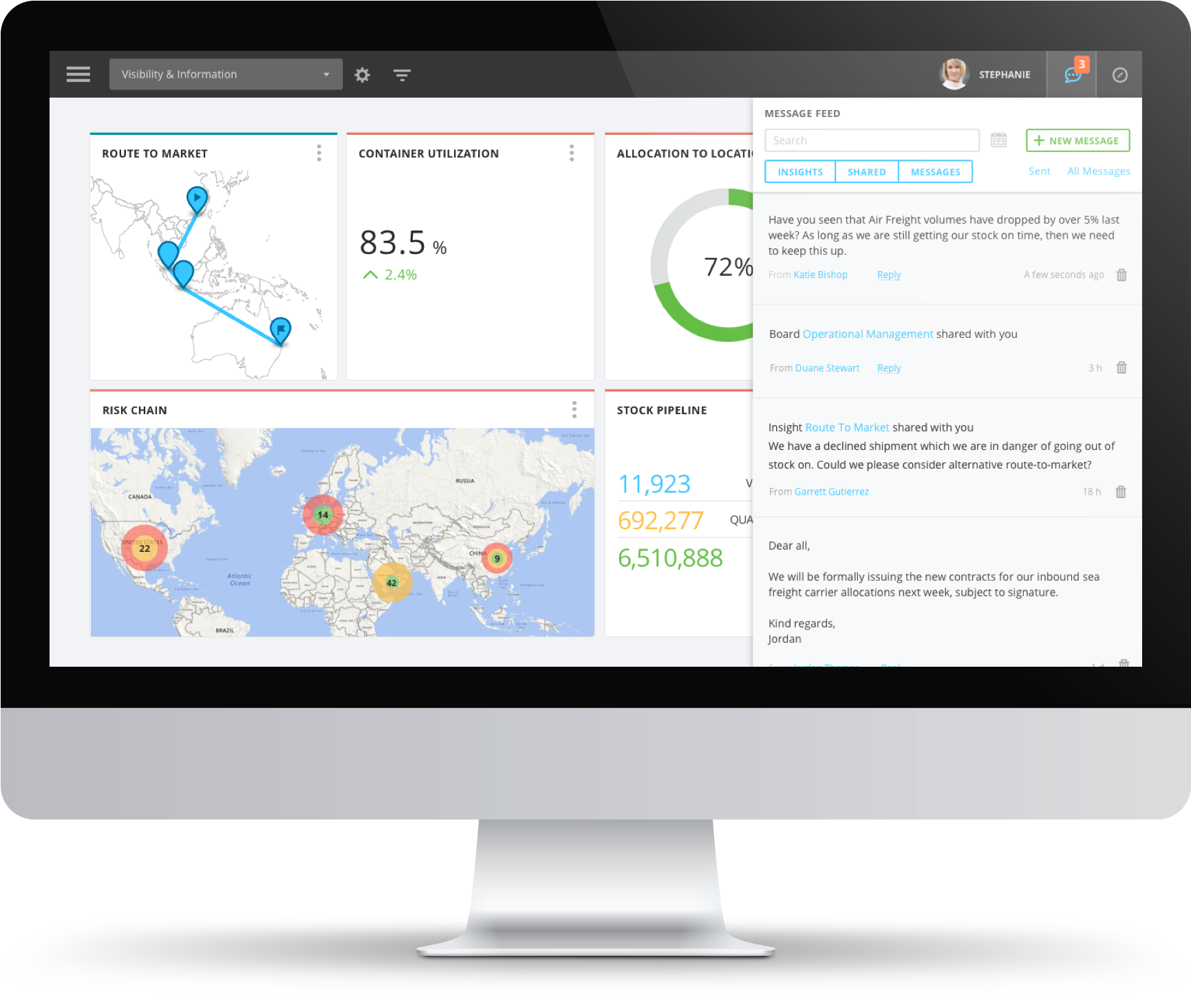

At the same time as bringing together all the different systems that operate in a supply chain, or supply network, we are doing the same for the people. We are giving them the tools to see what is happening in real time and to talk to each other either as a group across different companies or as individuals.

By having everybody on one common platform, and removing the need to extract data from one system, email it to somebody else, and then have that person key it into another system, our users can focus on adding value to their business rather than their inbox.

Thirdly: Actionable Insights From Predictive Analytics

Our focus on a clean, simple, intuitive user experience allied with our predictive analytics capability gives a user the information they need to react to demand or plan with a more informed and reliable sense of what’s going to happen in the future.

| Gravity User Interface |

It’s always a frustration of mine when people refer to their month-end KPI packs and how vital they are to run a supply chain.

The fact that the KPI pack is produced only every four-five weeks after the activities it is measuring has taken place, means that by its very definition it can’t be “key.” It’s too late then to do anything about what has occurred previously, and indeed what is happening now. That means you are going to be six-seven weeks behind what’s going on in your supply chain at the very best.

Our ambition is not only to tell you what’s going on at this exact minute but what is going to occur tomorrow, what the impact of this will be on your customer experience promise next week and ultimately what it is that you need to do next.

Finally: Automation.

The absolute key to delivering a customer experience free from friction points is focusing on the customer – being customer-centric. Technology alone won’t do this; it is an enabler, but it’s still the people within a business who can truly make or break whether they keep their customers’ interest and loyalty.

However, in the majority of companies we see, their people are still focused on moving data or pieces of paper around. They are re-keying information that has come from a different party or producing reports or documents because some of the underlying data is missing from their systems. The reluctance to automate or upgrade to new supply chain technologies can create new friction points and/or calcify existing ones, hindering profit growth in the form of operational inefficiencies and poor customer experience.

Our ability to receive or collect the data from any source, make sense of it, standardize it, and then reuse it, is at the heart of the value of the Gravity platform.

If you’d like to talk about the friction points in your business and to see if the Gravity platform might be a good fit for you, request a demo today.