Currently, the U.S. and China, find themselves embroiled in a highly publicized trade war. It was initiated in 2018 when the Trump administration started implementing tariffs on Chinese exports to the U.S., with China retaliating by imposing import fees of its own on American goods. Both countries had imposed 25 percent tariffs on US$50 billion worth of each other’s imports. And just recently, the US announced that it would enforce 10% tariffs on an additional US$200 billion worth of goods from China from 24th September. China countered by implementing tariffs on US$60 billion worth of American products.

Tariffs Increase Business Costs

The long term impact of the tariffs may be that the U.S. and China will enter into trade negotiations that will benefit the economies of both countries, such as making it easier for U.S. companies to invest in China and vice-versa. However, the immediate impact of the tariffs is that they will make it more expensive for American companies, manufacturers, retailers, and suppliers to import products or raw materials from China. American firms will also find it costlier to export goods into China.

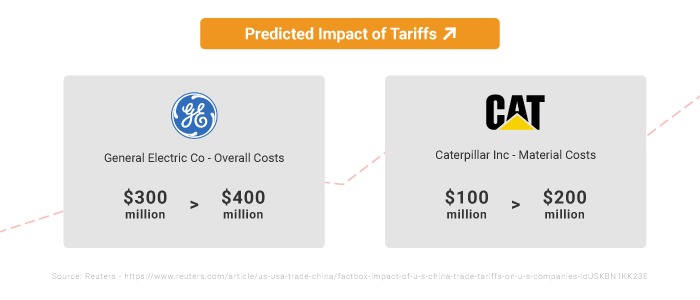

Given that China is the largest trade partner of the U.S. according to the U.S. Census Bureau, which estimated that bilateral trade between China and America reached US$636 billion in 2017, the reciprocal tariffs will increase the costs of a large proportion of U.S. based companies. Many noteworthy US corporations have already attested to this fact. For example, General Electric stated that new tariffs on its imports from China could raise its costs by US$300 million to $400 million. Caterpillar claimed U.S. tariffs on imports from China would increase its material costs by around US$100 million to $200 million in the second half of the year.

How Companies Can Mitigate Tariffs

In light of these increased costs of importing from China, companies may choose to either absorb the higher expenses, which will lower their margins. Or they may decide to pass on the increased costs to their customers by raising the prices of their goods, but this may reduce demand for their products, negatively impacting sales.

The most effective way for companies to cushion the impact of tariffs is to find ways to make their business run more efficiently, which will reduce operating expenses and offset any increased costs due to tariffs. One powerful way of making business more efficient is through digital transformation. And organizations involved in bringing products to market should look to digitally transform their supply chain as a significant step in improving the productivity of their business.

Digital Transformation of the Supply Chain

Here are three ways that digital transformation of the supply chain can improve business revenues and margins, offsetting any impact of tariffs.

1) Automation of time-consuming manual processes

Supply chains are complex operations with hundreds or thousands of people involved. And while recent technological advancements have made supply chain management easier, many companies still rely on manual tasks to collect, review and input data; including manual data entry – keying in data for purchase orders, bookings, invoices or quotes – which often involves copy and pasting such data from another system. If you multiply this type of repetitive, mundane activity by the number of times an employee does it in a week, it quickly adds up to a lot of wasted time. Also, manual tasks are hugely error prone, inconsistent and difficult to track. The result is poor visibility and insights that are inherently flawed due to being based on substandard data-making it difficult to stay on top of what’s happening in the supply chain and diminishing the ability to make smart data-driven decisions.

Businesses can invest in a digital supply chain platform that automates such data entry, by automatically collecting and updating the data from relevant sources, accessible in a single system rather than spread across multiple systems that don’t communicate. Such automation streamlines workflows, saving supply chain managers hours of time, and saving the company money since managing the supply chain can now be done much faster. For example, with Gravity’s Route To Market (RTM),you can automate the process of choosing the best sailing schedules for 100 major ocean carriers, covering over 90 percent of global container capacity; this gives managers more time to spend on activities which grow the business, such as negotiating better vendor prices.

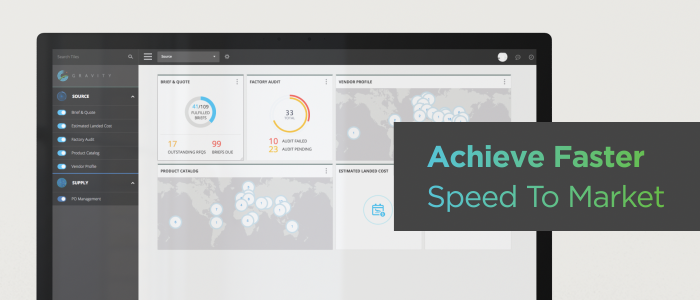

2) Faster speed to market

In today’s world, thanks to the likes of Amazon, smart technologies and mobile devices, consumers want products as quickly as they can get them. Businesses which fail to provide their customers with what they want, as soon as they want, will lose sales opportunities and market share to competitors.

The ability to get products to consumers quickly is contingent upon the speed of a company’s supply chain. By digitally transforming their supply chain, companies can achieve much faster speed to market. Why?

First of all, a digital supply chain provides real time visibility on the movement of goods across a company’s supply and logistics networks, from product conception to transit to arrival at destination. This visibility allows companies to make data-driven decisions to ensure the timely delivery of products. For instance, Gravity provides an early warning system that announces if a shipment might become delayed due to, for example, port congestion; allowing a company to take remedial action, such as air freighting inventory from another warehouse to make up for the delayed shipment. Watch this video to learn more.

Furthermore, a digital supply chain provides a single platform through which all supply chain partners, from businesses to logistics providers, to suppliers, can all share information and collaborate seamlessly, facilitating teamwork and reducing misunderstandings, all of which contribute to a faster delivery timeline.

Lastly, the automation of manual processes, as mentioned above, means less time spent on administrative work, and more time spent on optimizing deliveries.

Through faster speed to market, companies will increase their sales and revenue.

Learn how Gravity’s Source product can improve your speed to market.

3) Source products for cheaper

When a company’s regular suppliers are charging extra due to tariffs (or any other reason), organizations are forced to look for alternative supply partners or even new supply markets that can offer better prices. A digital supply chain platform can support sourcing teams to make the data management aspects of this process seamless, by providing a single platform to onboard vendors, send briefs, receive and compare quotes all in one place (rather than spread across various emails, systems, and documents). In this way, a business can take new vendors onboard and compare their quotes quickly and painlessly, so allowing them to identify which vendor is offering them the best value quickly.

Learn how Gravity can help you source products for cheaper.

Take Back Control

Tariffs, like corporation tax, are external economic pressures, which affect the bottom line of companies, but over which businesses have little or no control. The supply chain, however, is something over which companies do have control. By digitally transforming their supply chains, companies can become much more efficient at what they do, helping them offset tariffs and other external economic overheads.