The inevitability of supply chain disruptions in a global environment is one that’s well understood. Businesses need to employ strategies that are agile, proactive, and resilient creating a no-risk supply chain to mitigate risks and ensure business continuity.

SOURCING DECISIONS

In today’s incredibly competitive business environment, both profit and customer service levels must get carefully considered, making sourcing decisions crucial but often problematic. Businesses need to consider the rationale of low-cost longer lead-time sourcing vs. more expensive nearshore and onshore options, with one eye firmly on the consumer demand and satisfaction as well as the carbon footprint and sustainability.

With a combination of these options, and with the correct level of visibility, and connectivity, the supply chain, and ultimately the value chain is not impacted. Moreover, it gets designed to mitigate risks and disruption, such as the impact we are witnessing currently due to the coronavirus – COVID-19.

OFFSHORE VS. NEARSHORE

In recent years, many industries have witnessed a transition from offshoring to nearshoring. This transition is a result of numerous factors to include:

- the volatility of oil prices

- the need to reduce lead-times

- modern-day high demands and expectations

- the mitigation of potential supply chain disruptions

All of which can significantly affect the entire supply chain.

SOURCING STRATEGIES AMID TURBULENT TIMES

The trade war between China and the U.S. was the beginning of disruption felt throughout the sourcing process, with U.S. retailers needing to reconsider their sourcing origins and decisions.

The COVID-19 global pandemic has further and significantly highlighted the need to evaluate single-sourcing strategies and the high dependency on China. However, it’s highly probable that these complications and uncertainties will get further fuelled by a trade war that no longer only exists between China and the U.S., but is now shaping up to be between China and the rest of the world.

Fundamentally, we must consider that the factories and sourcing opportunities in other pivotal manufacturing origins, such as Bangladesh, Myanmar, Cambodia, will likely not be the same as pre-COVID-19. Given the considerable amount of cancellations, and significantly reduced orders, factories that were once essential employment and manufacturing bases, may not be around in the same quantity to resume operations.

All of these factors point toward a need to shift the focal point toward not only sourcing strategies, but alignment, and visibility throughout the entire process. Doing so will provide each stakeholder within each entity, clear transparency, traceability, and ultimately accountability, in the push for a far more sustainable value chain model.

VISIBILITY IN A VOLATILE WORLD

The world is becoming increasingly volatile and uncertain; both natural and man-made disasters continually create disruptions with the power to significantly disrupt even the strongest of supply chains. Creating a truly connected digital supply chain is crucial.

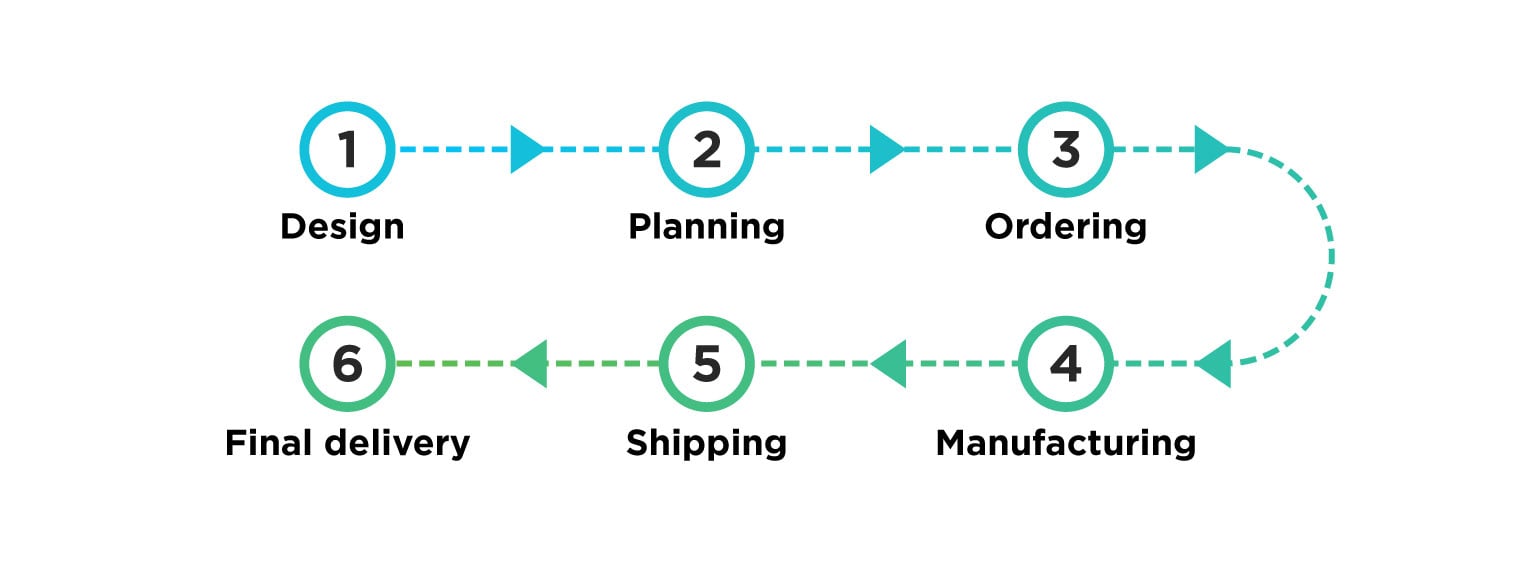

Having real and accurate visibility throughout the entire process is paramount, from:

Complete transparency and alignment must get enabled regardless of whether production takes place nearshore or offshore. If the logistics teams can see the buying patterns earlier, and the optimizers and allocators can see the production and shipping, decisions get made with certainty.

CONNECTED ECOSYSTEMS

When risk becomes apparent, having a connected ecosystem view of your entire critical path, decisions to change production origins, cycles, or capacity is not only visible to everyone but allows for proactive decision making a lot earlier.

The supply chain entails more than just the shipping element.

TECHNOLOGY MITIGATES RISK

Businesses must deploy strategies and tactics for building supply resilience. Using technology such as that provided by Gravity helps to mitigate risk through the provision of extensive predictive analytics delivered in real time to ensure decision-making takes place with certainty. Having a truly connected platform capturing sourcing, purchase order management, shipping, and landside to the distribution centers ensures everyone involved has sight and accurate information. In moving away from siloed departmental functions and control, a customer-centric value chain environment is established.